rockwell hardness test for composite materials|rockwell hardness testing procedure pdf : private label The Rockwell hardness test, according to ASTM E18-24, is an indentation hardness test that involves the use of a verified machine to force a diamond spheroconical indenter or tungsten carbide (or steel) ball indenter . Resultado da Bimi Sushi - Kapiti Coast, Paraparaumu Beach. 132 likes · 2 were here. Serves tasty sushi | hot food | sides since 2006

{plog:ftitle_list}

Com a Bipa, você paga 💵, recebe 🎉, envia Pix e compra Bitcoin & Dólar (USDT) a partir de R$1 🔥 de forma simples, rápida e segura. Compre e venda Bitcoin ou Dólar (USDT) em segundos. Faça parte da revolução do dinheiro! Envie, receba, pague suas contas e compre Bitcoin usando Pix. Peça o seu agora!

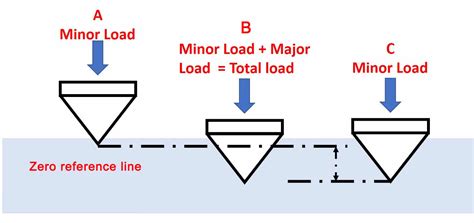

The Rockwell Hardness test is a hardness measurement based on the net increase in depth of impression as a load is applied. Hardness numbers have no units and are commonly given in the R, L, M, E and K scales. Higher numbers indicate harder materials.In hardness testing according to Rockwell, the total test force is applied in two steps. This is intended to eliminate effects from the roughness of the specimen surface (e.g., grooves on the specimen) as well as measurement errors .

rockwell hardness testing procedure pdf

The Rockwell hardness test, according to ASTM E18-24, is an indentation hardness test that involves the use of a verified machine to force a diamond spheroconical indenter or tungsten carbide (or steel) ball indenter .The hardness testing of plastics is most often measured by the Rockwell hardness test or Shore (durometer) hardness test. Both methods measure the resistance of the plastic toward indentation, thereby providing an empirical . Rockwell testers measure hardness based on the depth of penetration of an indenter into the surface of a material under a known load. Superficial Rockwell is used when the material being tested is relatively thin . A variety of standardized mechanical tests on composite materials including high-force tension (tensile), compression, impact, flexural, shear, rheology, and fatigue are known. .

Indentation hardness value is obtained by measuring the depth or the area of the indentation using one of over 12 different test methods. Learn more about hardness testing basics here. The Rockwell hardness test method, as defined .

The Rockwell test consists of measuring the additional depth to which a carbide ball or Brale® diamond penetrator is forced by a heavy (major) load beyond the depth of a previously applied .The Rockwell hardness test uses a spherical steel indenter; hardness is determined from the penetration depth. For Rockwell hardness, there are two conditions that are used for polymers. . Izod impact test and Rockwell hardness tests are performed on the four composites specimens as per ASTM standards. Experimental results reveal that by adding .The shore hardness test uses pin-shaped indenters, whereas a Barcol indenter is used in Barcol hardness testing. In this test, ASTM D785-08 (2008) and ASTM E 18-11 (2011) methods can be applied for measuring the hardness. For Rockwell hardness test in silk composites samples, a total of 10 indentation points can be measured on the samples .

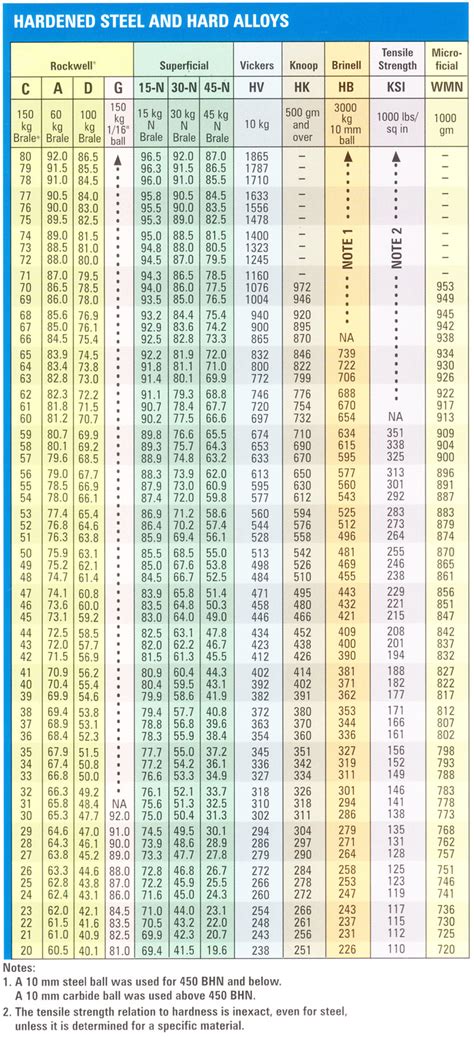

2 inch diameter, are used when testing materials such as steel-copper alloys, aluminum and plastics to name a few. Rockwell testing falls into two categories: Regular Rockwell testing (e.g., C and B scales) and Rockwell superficial testing (e.g., 30 N and 30 T scales). High Rockwell hardness numbers represent hard materials and low numbers soft . Rockwell hardness test is the most commonly used method for indentation hardness measurements. The value of Rockwell hardness is accompanied by the scale used. . Even ceramic and composite material .

The Barcol hardness test characterizes the indentation hardness of materials through the depth of penetration of an indentor, loaded on a material sample and compared to the penetration in a reference material. The method is most often used for composite materials such as reinforced thermosetting resins or to determine how much a resin or plastic has cured.Hardness Methods: The Rockwell hardness test measures the depth of penetra-tion of an indenter into a material under a known load. It provides a hardness value based on the depth of penetration. Rockwell Hardness The Brinell hardness test involves indenting a material with a hard sphere under a specific load. Two diameters (x and yISO 6508-2:2015, Metallic materials — Rockwell hardness test — Part 2: Verification and calibration of testing machines ISO 6508-3:2015, Metallic materials — Rockwell hardness test — Part 3: Calibration of reference blocks 3 Principle An indenter of specified size, shape, and material is forced into the surface of a test specimen under two

A Rockwell hardness tester. The Rockwell scale is a hardness scale based on indentation hardness of a material. The Rockwell test measures the depth of penetration of an indenter under a large load (major load) compared to the penetration made by a preload (minor load). [1] There are different scales, denoted by a single letter, that use different loads or indenters.Aim: To determine the Rockwell hardness for hard materials such as hardened steel & moderately hard materials such as brass. Theory: Hardness is a material characteristic which can be defined as resistance to deformation (penetration, wear, compression etc.) In Rockwell hardness test, a standard load (based on type of material) is applied through aASTM E 18-07 Standard Test Methods for Rockwell Hardness of Metallic Materials is the active and current standard by which Rockwell Hardness Testing is performed, and is also the most frequently used hardness testing method . Composite Testing; Corrosion Testing; Creep Testing; CTOD Testing; Fatigue Testing; LCF Testing;What is Rockwell hardness testing? The Rockwell Hardness Test is generally a non-destructive test performed on samples when it’s necessary to determine how hard a material is. It’s generally considered easier to perform compared to other methods, like Vickers or Brinell hardness testing. Another advantage is the small area of indentation needed to carry out the .

On further inspection to study the use of particulate matter as reinforcement, it was found that a research on composites based on epoxy resin and filled with iron, ferrite, graphite, coal powders were characterized [4] where Influence of concentration, parameters of casting and type of filler on composites properties was researched. Glass powder [5] also has been used .NOTE Attention is drawn to the fact that the use of tungsten carbide composite for ball indenters is considered to be the standard type of Rockwell indenter ball. . ISO 6508 consists of the following parts, under the general title Metallic materials — Rockwell hardness test:The Rockwell hardness test is an essential tool in material science, offering a fast and trustworthy way to measure how hard materials are, with a special focus on metals. This technique gauges how deeply an indenter presses into a material under a heavy load compared to its penetration under a lighter one. Composite materials testing plays a vital role across the composite's supply chain and product life cycle. (Detailed Guide) Home. About ATIRA; Organisation; Activities at ATIRA; . Physical testing. Hardness (Barcol, Rockwell. Shore) (ASTM E 18, ASTM B 254, ASTM D 2583 & Equivalent standards)

Attention is drawn to the fact that the use of tungsten carbide composite for ball indenters is considered to be the standard type of Rockwell indenter ball. Steel indenter balls may continue to be used only . ISO 6508-3:2015, Metallic materials — Rockwell hardness test — Part 3: Calibration of reference blocks 3 General conditions

The Rockwell hardness test method, as defined in ASTM E-18, is the most commonly used hardness test method. You should obtain a copy of this standard, read and understand the standard completely before attempting a .Thickness of the material The Rockwell M hardness test is not valid for plastics that are less than 0.05 inch (1.27 mm) thick. This is because the indenter can penetrate too deeply into thin materials, giving a falsely high hardness reading. . For example, metals, plastics, ceramics, and composite materials (such as fiberglass and carbon .

This test method includes requirements for the use of portable Rockwell hardness testing machines that measure Rockwell hardness by the Rockwell hardness test principle and can meet all the requirements of this test method, including the direct and indirect verifications of the testing machine. Portable Rockwell hardness testing machines that .You may purchase the ASTM standard from the American Society for Testing and Materials, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, Phone 610-832-9585, www.astm.org. . Standard Test Method for Macro-Rockwell Hardness Testing of Metallic Materials: F1957 : Standard Test Method for Composite Foam Hardness-Durometer .

rockwell hardness testing guide pdf

The interest in polymer composite material reinforced natural fiber is increasing every day [5], [6], . Test specimens of C1, C2, C3 and C4 composites for Rockwell hardness test were illustrated in Fig. 2. A 1/16″ ball type indenter was used to make an impression on the hardness test specimens, 60 kgf loads was applied on the test specimens . The Rockwell hardness test continues to be applied as a tool for assessing the properites of a product while the tolerances on the acceptable material hardness have become tighter and tighter. Adhering to good practice procedures when performing Rockwell hardness measurements and calibrations is a beneficial step to reducing measurement errors. Rockwell Hardness of Metallic Materials 1,2 This standard is issued under the Þxed designation E18; the number immediately following the designation indicates the year of original . Rockwell hardness testing machine that is designed to be 4 Available from American Bearing Manufacturers Association (ABMA), 2025 M Street, NW, Suite 800 .

Uncured materials will show low hardness. Size of the material – Testing the hardness of thin materials can be difficult. Hence it is important to check the size specifications of the material. What are the test methods to measure Shore D Hardness? The test methods used to measure Shore D Hardness are: ASTM D2240 and ; ISO 868The plastics industry applies a variety of hardness testing methods, and each method addresses a different measurement objective. They can be in the nano, micro, or macro range. Plastics brochure Test methods Shore ISO 48-4, ISO 868, ASTM D2240 Ball indentation ISO 2039-1 Rockwell ISO 2039-2/ASTM D785 Instrumented hardness testing ISO 19278 Videos .

3.1. Rockwell Hardness Test. . , indicates that hardness may not be a fundamental property of a material, but rather a composite one including yield strength, work hardening, true tensile strength, modulus of elasticity, and others. In the Rockwell method of hardness testing, the depth of penetration of an indenter under certain arbitrary .The Brinell method is suitable for hardness testing of soft metals (light metals, lead, tin) as well as hard metals, such as steel and iron.. Brinell testing of a material with different ball diameters and test forces must be conducted within the same force-diameter index („Brinell test procedure“) in order to enable direct comparison of the measured hardness values. Four Material Hardness Test Methods. . Industrial Use: Versatile for different materials, including metals, ceramics, and composites. Rockwell Hardness Test. Measures the depth of penetration of an indenter under a large load compared to the penetration under a preliminary minor load.

coronavirus testing hard rock stadium

rockwell hardness test calculation

WEB29 de jan. de 2024 · Free and open company data on Curaçao company Bravalla B.V. (company number 147847), Korporaalweg 10.

rockwell hardness test for composite materials|rockwell hardness testing procedure pdf